In the context of the appreciation of the renminbi and the global economic crisis, resistor manufacturers are facing increasing production costs and product price pressures. In recent years, fierce competition has also reduced the profit margins of manufacturers. When the world economic environment is turbulent, market demand is expected to decline, and product sales will also have a more profound impact.

Despite the prospects of manufacturers in the industry, they are still optimistic about the development of the industry, because the global demand for consumer electronics, communications, automobiles, computers and military resistors continues to increase, giving them optimistic capital. At present, China is in a leading position in the resistor industry in the world. According to the data of China Electronic Components Industry Association, the total output of China's resistors in 2008 was 708 billion, which is only a huge increase compared with 410 billion in 2005, and it accounts for the world supply. 30% of the total. Since 2005, the scale of China's resistor production has grown at a rapid rate of 20% per year, and the association's total output will reach 850 billion in 2009.

China's resistor industry has achieved rapid development during the national "Tenth Five-Year Plan" (2001~2005). After the 2001 "accession to the WTO", through the policy of opening up the international market and improving product development, it strives to consolidate its leading market position in the global resistance market. Device.

Leading position in demand for chip resistors.

At present, China's chip resistors account for 85% of the total output resistance. In order to get a share of the demand from emerging markets, more and more companies are expanding production scales with high resistance and producing core chip products. It can be expected that in the next few years, it will continue to lead the production of local chip resistor resistors in China. Driven by the demand for chip resistors in the global mobile communications, computers and peripherals, digital consumer and automotive electronics industries, China’s local suppliers have very good resistance, especially portable electronic devices with low resistance, increased demand, low resistance, and miniaturization. The prospect of resistance is promising.

The sizes of domestic chip resistors are different. For consumer electronics and communication products, 0603 chip resistors are currently local resistors in China. The trend of miniaturization will promote the production of 0402 smaller size chip resistors. In response to market demand, manufacturers expect the output of 0603 and 0805, 1206 and other large resistors to decline in the next few months.

0402 chip resistors are used more and more frequently in electronic products such as mobile phones, MP 3, digital players, digital cameras, portable digital cameras, portable navigation devices and notebook computers. With the miniaturization of mobile phones and other electronic devices, manufacturers believe that the chip resistors used in these electronic products have become type 0402.

Chinese local manufacturers also plan to develop 0201 resistors. R&D strength not only increases the demand for new generation mobile phones, MP4 players and RF equipment, because they can bring more profits. Suppliers will test and produce 0201 chip resistors in 2009.

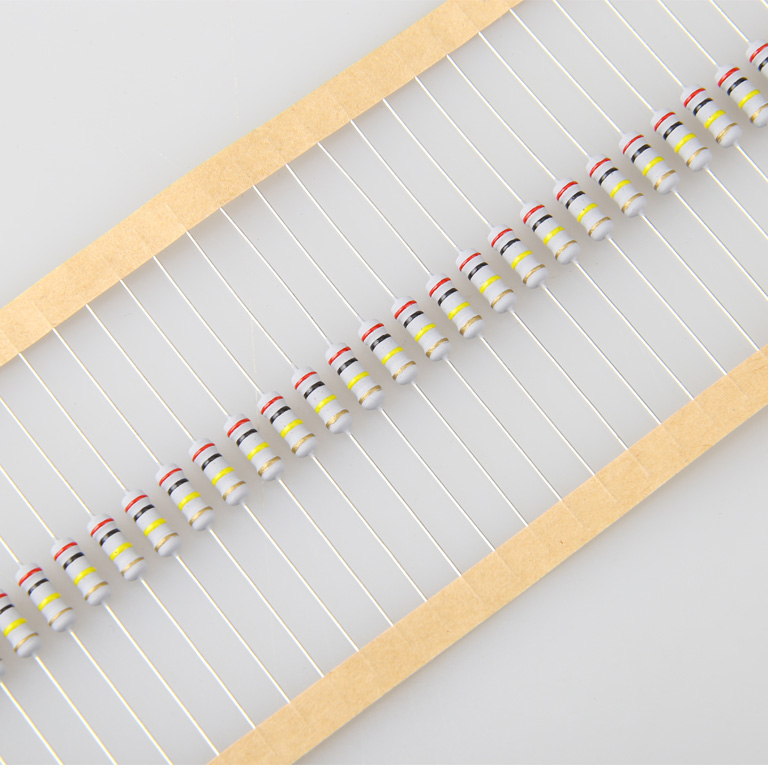

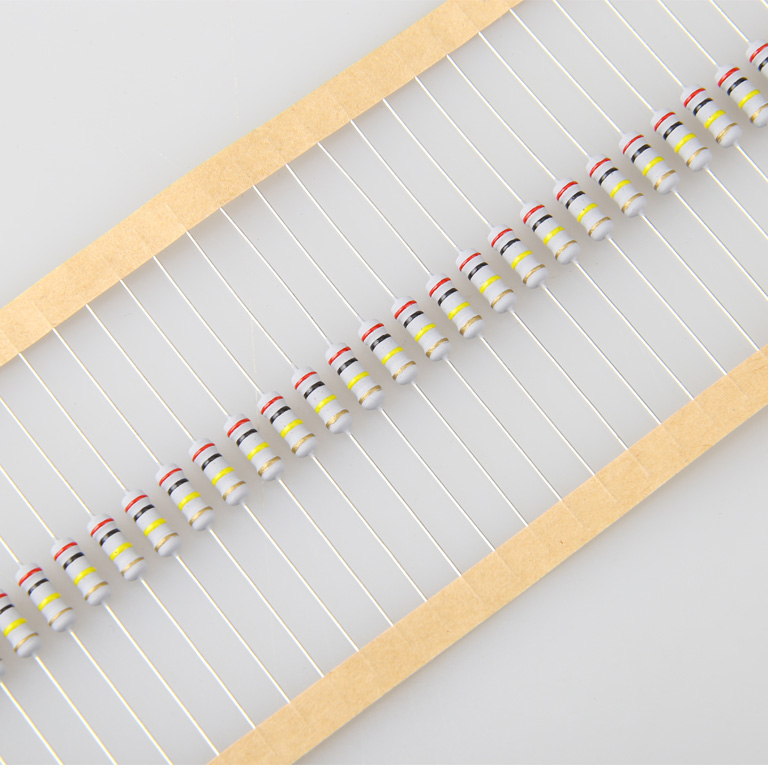

In addition to chip resistors, local Chinese manufacturers also produce plug-in resistors. Resistors are widely used in consumer electronics, industrial equipment and children’s toys. Spark plug resistors will continue to be used in high-power applications, because chip resistors cannot yet support applications with power above 3 watts. Therefore, no matter how fierce competition is for plug-in resistor chip resistors, the market will remain stable. According to Philips forecasts, the global electronics market will grow by 38.4%, greatly increasing the demand for plug-in components. In addition, as the demand in aviation, aerospace and military fields rises, the production of metal film resistors in China will increase.

The product technology is mature, and the performance improvement is mainly

With the maturity of the industry and major breakthroughs in resistance technology, manufacturers are still working hard to improve product stability and overall performance.

The development of products is mainly focused on high precision, high frequency and low temperature coefficient, lead-free and miniaturization are also the R&D focus of manufacturers.

For chip resistors, high-frequency, high-power products will be the dominant product development trend in the next few months, manufacturers will also introduce a thermistor, varistor, gas sensitive resistor, most suppliers are still chip type Thin film technology is used in resistance production.

In the field of plug-in resistors, carbon film resistors and metal film resistors are the most widely used in China and local shaft products. Compared with thin film resistors and mature technology, domestic and foreign manufacturers have fierce competition for product quality and cost control. For example, due to rising copper prices, many manufacturers have begun to use iron needles to maintain profitability.

Another part of the suppliers develop precision wire-wound resistors and cement resistors. Demand for different types of products and profit margins are considerable. Metal film resistors are developing towards low temperature coefficient and high precision, and many manufacturers have adopted advanced production equipment from Japan and Europe. Therefore, the supplier chooses nickel-chromium alloy, tantalum nitride and tin oxide imported high-quality raw materials to produce precision metal film resistors with low temperature coefficient.

For cement resistors, miniaturization, high temperature stability, good heat dissipation, low noise, low resistance, the development trend of changes is development, manufacturers are still wet, earthquake resistance cement resistance.

China's electrical industry.

Hundreds of resistor manufacturing plants in China are located in 18 provinces and cities in China. According to the data of the Electronic Components Industry Association, there are more than 60 manufacturers of carbon film resistors, and more than 40 manufacturers of metal film resistors and metal oxide films. There are 30 resistor manufacturers, and chip resistor manufacturers more than 30, most of which are Taiwan-funded enterprises.

The supply base consists of Chinese manufacturers as well as Taiwan-funded, Japanese enterprises, whose purpose is to provide resistance in the high-end market, and most of the Chinese suppliers’ products are supplied to the end of the market.

Most of the manufacturers are concentrated in the Yangtze River Delta and the Pearl River Delta, especially in Shanghai, Jiangsu, Suzhou, Dongguan, Guangdong, Tianjin and other provinces and cities. Among them, Guangdong and Jiangsu each have nearly three manufacturers, Shanghai and Tianjin each have 6, others The manufacturers are located in Zhejiang.

In fact, China still attracts computer, communication and digital electronic equipment manufacturers from all over the world to invest in China to establish production lines. All Taiwanese chip resistor leaders have established and back-end packaging bases in mainland China and upgraded to complete processing. factory. China's exports and resistors are also imported in large quantities, and the demand for chip resistors is increasing day by day, especially for high-end resistance.